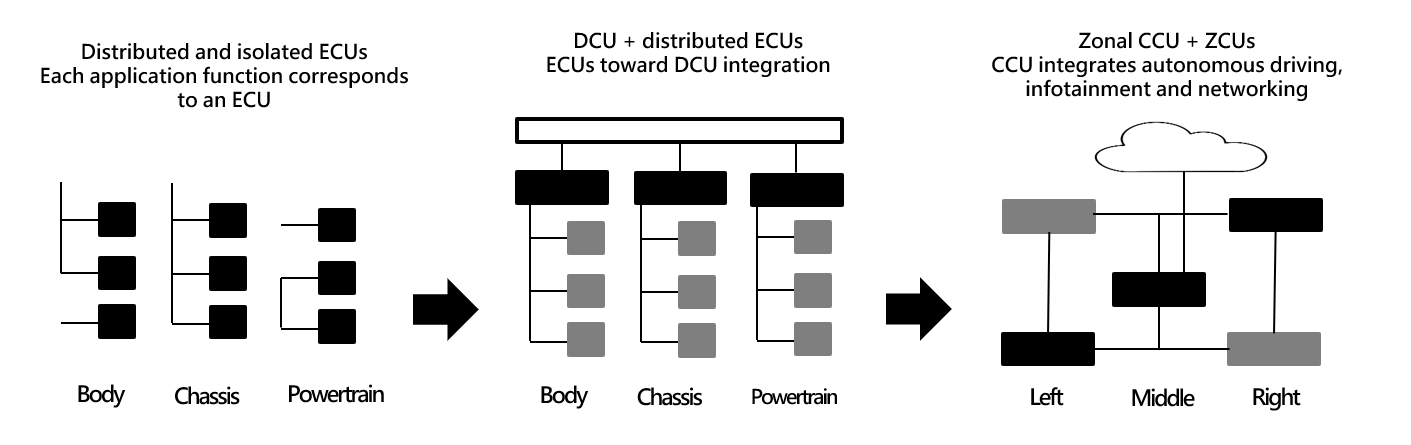

Since the 1980s, the electrification revolution started in the automotive industry, and the ECU (Electronic Control Unit) has become the core of system control. Currently, the electronic and electrical architecture is decentralized, with each vehicle having at least 25 ECUs, and high-end models usually have more than 100, and the traditional EEA (Electronic/Electric Architecture) also faces the problem of overly complicated connections. As shown in the figure below, to cope with the increasing number of domain ECUs year by year, a centralized architecture based on DCU (Domain Control Unit) was born, thereby reducing the weight of electronic components, and reducing the cost of vehicle manufacturing. Furthermore, to reduce the length of the bus connection and the problem of overly complicated wiring harnesses, the centralized architecture of each domain has been further integrated, giving rise to the regional architecture ZCU (Zonal Control Unit), which is responsible for the management and control of specific-regional functions. EEA has evolved from low-end ECU to mid-end DCU and then to high-end ZCU, which means that every step forward, the function of the electronic control unit must be more powerful, the performance is better, and the processing ability of the MCU is also required to be more and more high, the 32-bit processor has also become the mainstream of automotive applications.

Regarding the development of the automotive market, although the EE architecture of vehicles is being centralized, the number and functions of MCUs will continue to expand throughout the vehicle. According to Strategy Analytics, the number of MCUs will grow by approximately 8% from 2021 to 2026, exceeding the growth of automobile production, the output value of global 32-bit automotive MCU will double from US$3 billion to US$5.8931 billion from 2022 to 2029. In response to the growing demand of the automotive market, Andes Technology provides a variety of single-core/multi-core CPU solutions for vehicles. It not only has the competitive advantage of high efficiency and multi-configuration functions, but also provides diversified automotive safety designs, including error correction code (ECC), software test library (STL), dual core lockstep, etc., as well as overflow/underflow stack, physical memory protection (PMP) and other protection mechanisms, and also providing ISO 26262 compliance certification, making automotive chip development easier and more efficient. The following is a brief description of Andes Technology’s CPU automotive solutions and applications:

AndesCore™ D23-SE: 3-stage pipeline/single issue/ASIL D safety core, suitable for energy-saving and cost-effective ECU/DCU design solutions, supporting a wide range of applications from ASIL B to ASIL D, including Battery Management System, Anti-lock Brake System (ABS), Tire Pressure Monitoring (TPM), Electric Power Steering (EPS), Airbags, Motor Drive Control, Safety Island, etc. different applications.

AndesCore™ N25F-SE/AndesCore™ D25F-SE: 5-stage pipeline/single issue/ASIL B safety core, suitable for high-efficiency ECU/DCU design solutions, supporting a variety of ASIL B applications, including Vehicle Monitoring System, Body Control DCU, Blind Spot Monitoring (BSM), Touch and Display, Adaptive Cruise Control (ACC), Keyless Control, Vehicle Charger, In-car Storage and other different applications.

AndesCore™ D45-SE: 8-stage pipeline/dual issues/ASIL D safety core, suitable for high-performance ECU/DCU/ZCU design solutions, supporting a wide range of applications from ASIL B to ASIL D, including Millimeter Wave Radar Sensor, Around View Monitor system (AVMS), Vehicle Instrument Cluster, Powertrain DCU, Infotainment DCU, Front/Rear different applications such as ZCU.

The Andes Automotive Ecosystem

Andes and ecosystem partners jointly deliver the trusted RISC-V automotive solutions to designers complying with the standard of functional safety ISO 26262